About

About YCM

Vision

“Sustainable development, Becoming one of the top value machine tool manufacturers in the world” has been the vision of YCM. With the mission of being the first Taiwanese manufacturer awarded the certificate of the ISO-9001 Quality Assurance System and ISO-14001 Environmental System authorized by Bureau of Standard, the Ministry of Economy Affair, YCM has proved itselves to be a leading role in machine tool industry. To benefit customers, YCM offers remarkable products, perfect service, and punctual delivery time as our core value.

Vertically Integrated Production System

In Taiwan's machine tool industry, YCM is the only manufacturer who operates its own foundry. What's more, we manage entire manuafactering process under rigorous quality control over machining facility, spindle assembly shop, assembly plant and packaging warehouse. That's why you could find YCM machine highly sophisticated.

R&D Technology

In response to fierce competition in manufacturing around the world, transforming to Industry 4.0 has become imperative. With respect to this trend, YCM has made great efforts in integrating manufacturing management, smart machines and automation.

With the core values of high quality, excellent technology, perfect service, YCM has complete production lines comprising of vertical machining centers, horizontal machining centers, CNC turning centers and 5-axis double column vertical centers. YCM will also continue to develop multi-axis and multi-functional machining centers that will drastically improve customer productivity with smaller floor space that allows customers to make more with less.

To help customers continuously strenghten their competitiveness and achieve sustainable growth, YCM will offer total solutions covering automation and customization to optimize the manufacturing process. YCM can professionally provide you with the optimal suggestion based on the components, machine, jig/fixture and even IoT platform that will be well-suit to your production. With the continuing development of our i-Direct IoT platform, it is possible for customers to manage their shop with ease.

Sustainability

YCM Environmental Policies

- Conbining the Concepts of Environmental Protection Into Product R&D The product R&D appraises all possible environmental aspects as to the use of materials, manufacturing processes, sales, installation and service activities...etc. in compliance with the strict safety codes, recycling and efficiency enhancement to bring down the impact of a product to the environments as much as we can.

- Reducing Waste Material and Undertaking Pollution Precautions in All Activities By implementing surveys on significant impacts to environments from relevant activities and fostering certain organization and measures to assure our operations meet the strict requirements on environmental protection.

- Following the Law of Environmental Protection and Endeavoring the Best to Protect the Environment Through browsing web contents of the Environmental Protection Administration (EPA) and relevant sites, we gather information on environmental protection adn promise to follow the law in protecting the environment.

- Implementing In-House Training Courses to Promote the Enviromental Protection Knowledge on Every Employee

Every newly recruited employee must take part in such training; regular training courses on environment aspects are also given to all employees. - Comitted to Enhancing the YCM Environmental Management System (EMS) YCM will keep improving through the P.D.C.A managing cycle, we keep on improving our operation, especially related to the Environmental Management System.

- Communicating and Promoting the YCM Environmental Management System to the Public Spread our efforts and achivements of environmental protection to the public through catalogues, official website, media, banners, slogans and YCM EMS manuals.

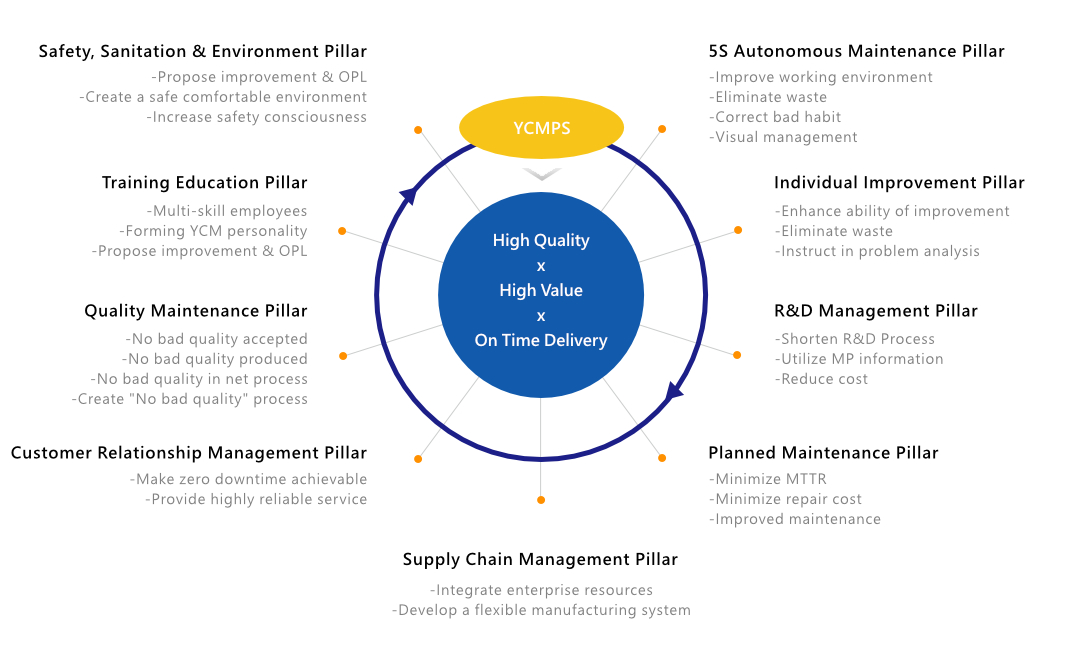

YCMPS

YCMPS is the abbreviation of Yeong Chin Machinery Production System. By learning the essence of “Toyota Productivity System”, YCM would like to innovate its own unique production system as well as integrating with the current production process.

TPS is based on two major concepts, “Just in Time” (JIT) and “Jidoka.” The purposes are to eliminate all kinds of waste and create an efficient process flow. The main idea of YCMPS is around 5S.

5S is the name of a workplace organization methodology which combines five Japanese words starting with the letter s, “Seiri, Seisou, Seiton, Seiketsu and Shitsuke.”, and these five Japanese words stand for five phases.

- Phase 1, “Seiri”, means sorting;

- phase 2, “Seisou”, means cleaning;

- phase 3, “Seiton”, means setting in order;

- phase 4, “Seiketsu”, means standardizing;

- phase 5, “Shitsuke” means sustaining the discipline.

By going through these 5 phases, every participant learns to eliminate all kind of waste and raises the company’s competence by offering customers the products with high quality and the greatest services. YCM strongly believes that constant internal improvements are the best solution for the company to develop sustainably in this competitive environment.