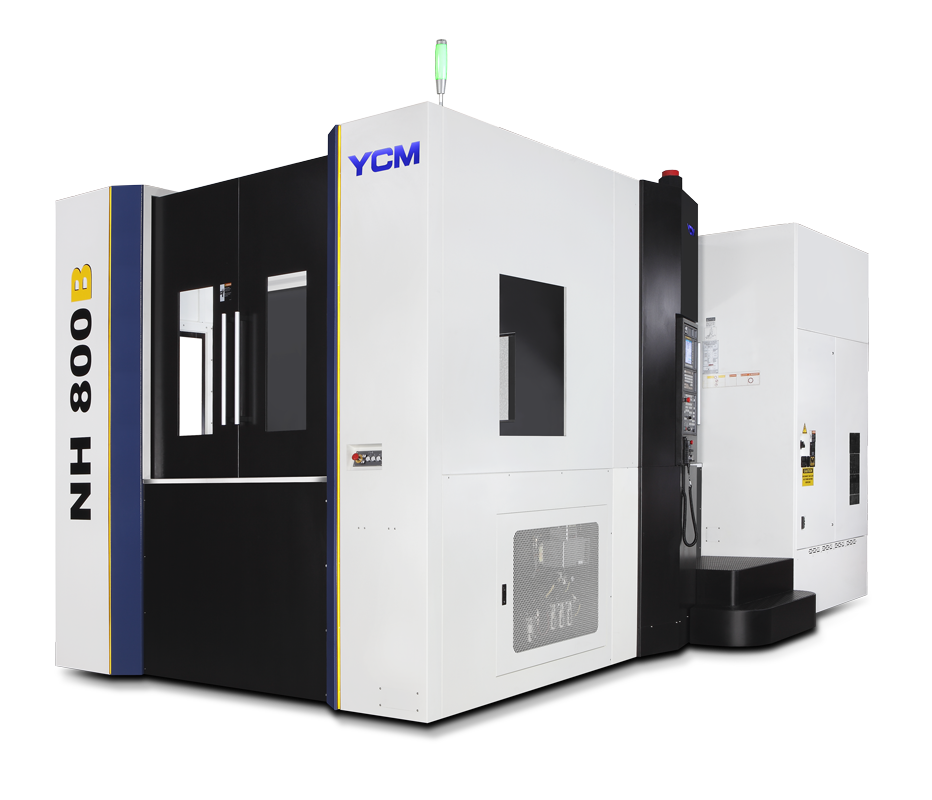

NH630B

Product

ProductInfo

High Rigidity Structural Design

- One piece T-base foundation with rib construction for unprecedented rigidity.

- Spindle headstock is made of one piece casting to ensure cutting rigidity and accuracy during long-period machining.

- Stepped castings design on X-axis to increase the cutting rigidity.

- Dual-wall column design for eliminating possible thermal deformation.

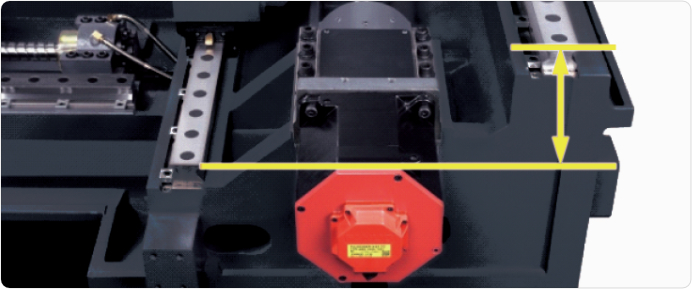

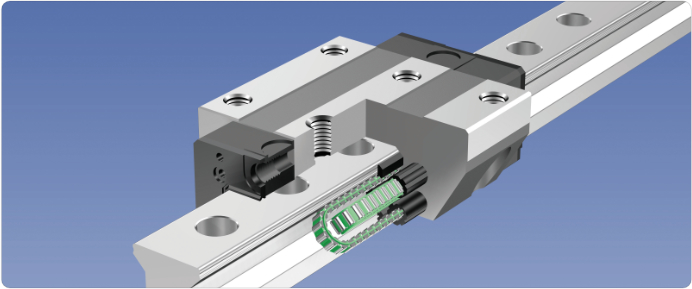

High Rigidity Roller Guideways

- Oversize roller guideways increase rigidity and precision.

- High dynamic AC servo driven pre-tensioned ball screws, delivering high control qualities.

- 60 m/min. rapid feedrate increase machining efficiency.

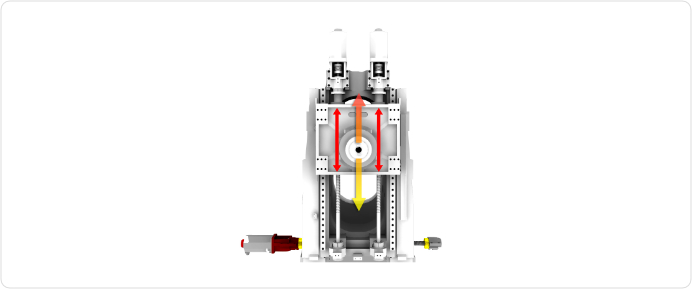

Y-axis Dual Drive System

- Headstock is driven at the center of the gravity to minimize vibration. The dual-driven design restrains vibration and delivers high speed, high quality machining ability while increasing machine performance and tool life.

High Performance Built-in Motorized Spindle

- Built-in motorized spindle reduces vibration during high-speed machining and ensures spindle life.

- 10,000 rpm maximum spindle speed with 45 kW output delivers 623 Nm torque.

- Micro oil-air lubrication for angular ceramic ball bearings prolongs spindle life.

- Circulated oil jacket cooling system minimizes thermal deformation, ensuring high accuracy.

High Capacity Machining Space

- ø1,100 mm x 1,000 mm largest working envelope within its rank.

- 1,200 kg maximum loading capacity on each pallet

Automatic Pallet Change

- 12-second pallet change.

- Servo motor driven.

- Simple structural design, fast reliable movement and easy maintenance.

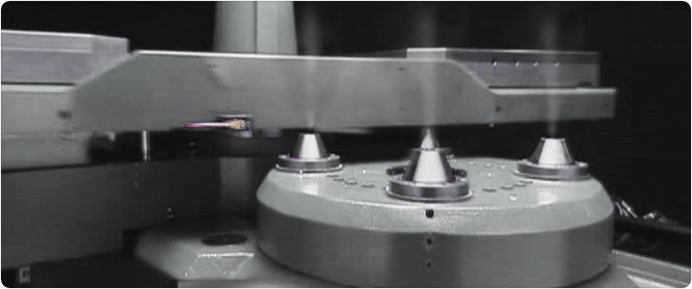

High Precision B-axis Rotary Table

- Disc brake with damped clamping system.

- High precision in-house pallet indexing system.

- Discharging air jet pallet indexing system.

Reliable Automatic Tool Change

- Servo motor driven tool magazine shortens tool search time.

- Short tool change arm with low moment of inertia design.

Central Chip Disposal System

- Chip removal design assures the chips to drop directly to the conveyor.

- Dual chip augers are utilized for efficient chip removal.

- Dual chip augers are utilized for efficient chip removal.

- Heavy duty coolant pump.

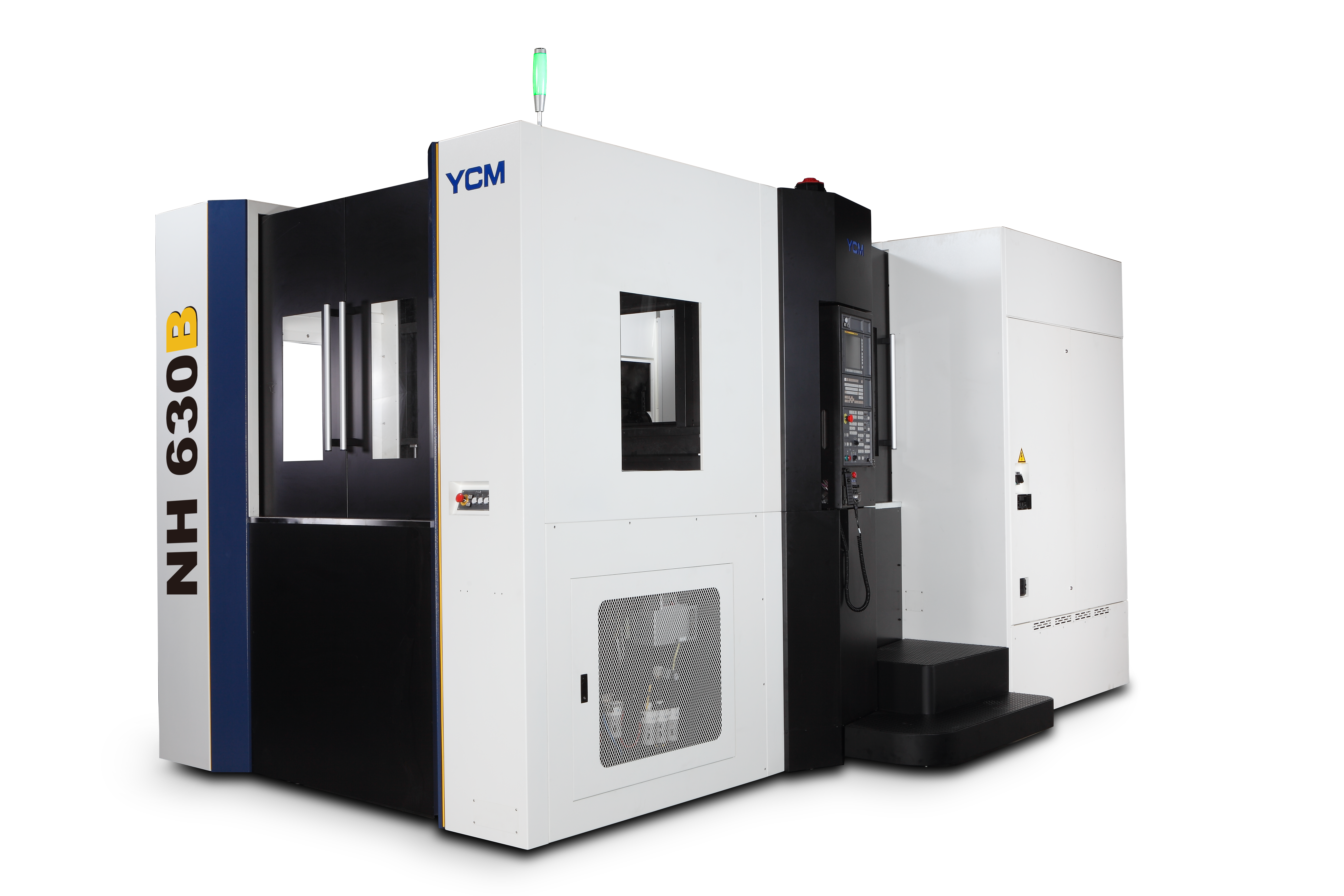

Compare

×

Product has been added to compare

You can select up to 5 products or view the results directly.