GT-250MA

Product

ProductInfo

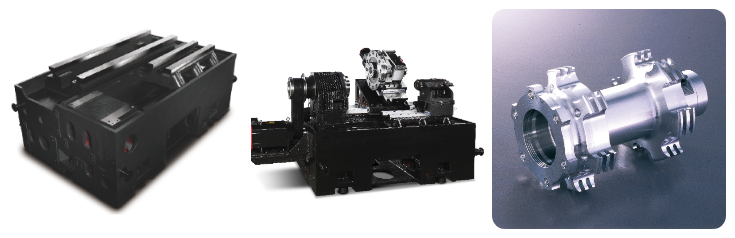

Ultra-stable and Highly Rigid Box-type Base Structure

- The box-type design offers a ultra-wide base structure, high quality MEEHANITE® castings, oversize hardened & ground boxed ways to ensure the best machining performance by eliminating structural distortion and deformation under heavy machining conditions.

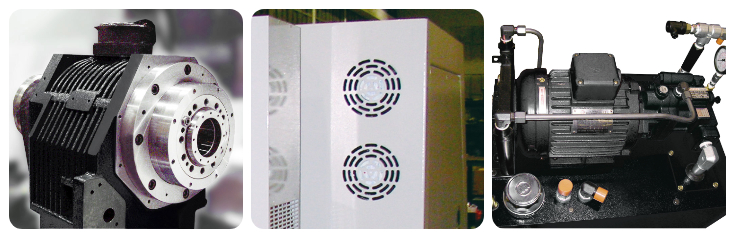

Unique Quill-type Spindle Cartridge

- All spindles are strictly assembled in temperature controlled room, and proven through rigorous run-in test to assure the highest quality and reliability.

- The unique quill-type spindle cartridge designed for easy maintenance and repair if necessary.

- Oversize dual roller spindle bearings are used in both front and rear of the spindle to provide optimal spindle rigidity that is capable of handling 10mm cutting depth on hard material.

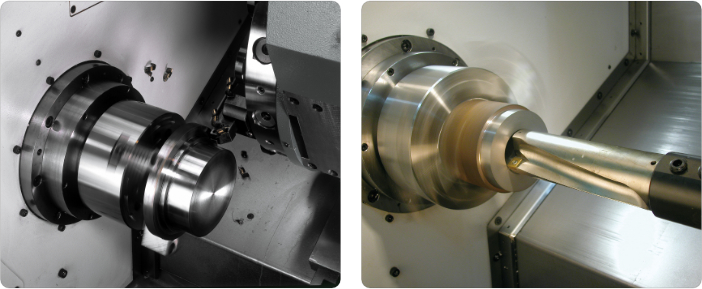

The GT series is ideal for high productivity turning and milling with exceptional speed, power, and capacity.

- Oversize hardened and ground box ways, ballscrew and bearings are essential requirements for enhancing the axial and radial cutting rigidity.

- High torque spindle motor provides the necessary power for roughing operation on tough material at low spindle speed.

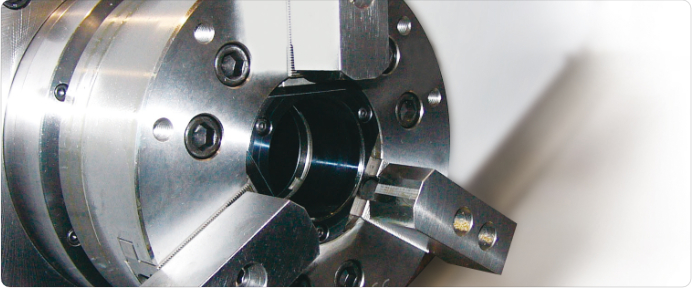

Heavy-duty Spindle Design and Durable Hydraulic Chuck

- High quality chuck with powerful hydraulic system ensures machining rigidity and accuraacy.

- Pressure sensors are added to hydraulic system for monitoring clamping force of chuck, assuring the proper clamping of heavy parts.

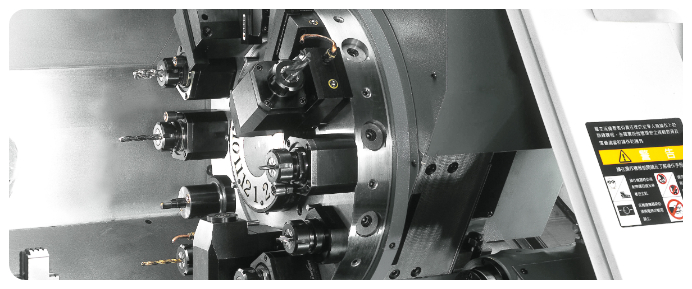

Powerful VDI Turret with Milling Functions

- Extra large turret 3-piece coupling is installed to assure the best milling performance.

- VDI turret is servo-driven for quick and reliable tool indexing; the adjacent tool index time is only 0.6 second that reduces non-machining time and improves productivity.

- The turret is designed with optimal tool arrangement to minimize the interference and maximize machine utilization for effective production capacity.

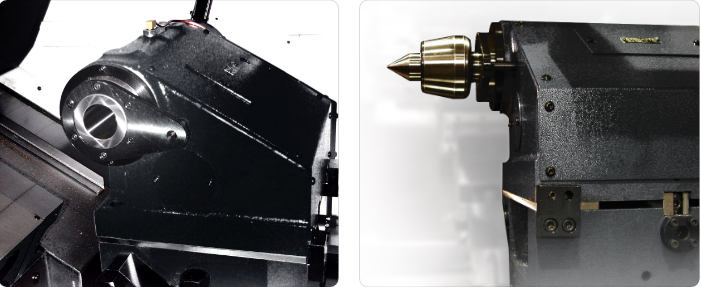

Versatile Tailstock Design

- The tailstock is supported by hardened and ground boxed ways that is structurally one-piece with the machine base, which ensures the best structural rigidity.

- The oversize quill supports heavy workpieces while maintaining machining accuracy.

- Optional live quill is ideal for high-speed, high production environment.

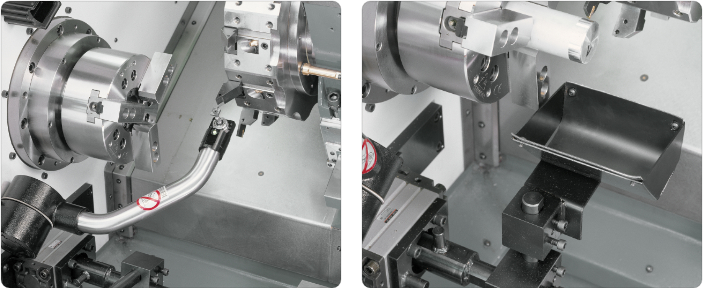

High Productivity Enhancements

- Automatic tool length measurement (opt.)

- Automatic bar feeder system (opt.)

- Automatic part catcher (opt.) and part conveyor (opt.)

Thermally Stable Design

- Symmetrically designed headstock combined with effective spindle headstock exhuast fans provide superior ventilation throughout the spindle compartment, help to minimize thermal growth.

- The spindle motor is mounted to the left side of the machine base and is designed to exhaust the heat generated from spindle motor away from the machine structure.

- High-performance hydraulic piston pump provides high efficiency and low heat minimizing the thermal impact of hydraulic system.

- Isolated coolant tanks minimizes the effect of coolant temperature fluctuation, reducing potential structural deformation.

- Low heat generated work lamp is installed to minimize temperature impact.

Compare

×

Product has been added to compare

You can select up to 5 products or view the results directly.