NSV106AMS

Product

ProductInfo

High Rigidity Design

- One-piece motor housing

- Large delta machine column and base ensure the highest stability during high speed movement.

- Advanced FEM analysis strengthens the structure while reduces the weight to provide the best cutting rigidity.

- 3 axes equipped with 45 mm roller guideways and large-diameter ball screws maximize chip disposal during processing.

- X-axis equipped with 6 slide blocks increases rigidity by 50%, compared to previous model.

- Y-axis guideway span with optimal ratio

- Its table can easily support workpieces weighing up to 1,000 kg.

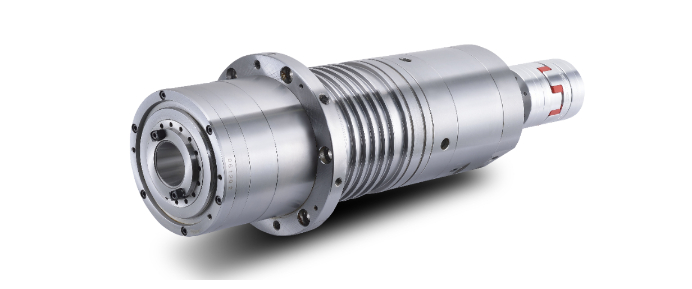

IDD PLUS Spindle Design HIGH PRECISION HIGH SPEED

- The unique IDD spindle design offers smooth reliability at high speed.

- Ceramic bearings not just boost the spindle speed, but also achieve high axial and radial rigidity, which fulfill strict machining requirements on heavy cutting, drilling and tapping.

- Spindle cooling unit decrease thermal deformation on spindle headstock.

- Micro oil-air lubrication system minimizes thermal deformation and prolongs spindle life that are well-suited for die & mold industry.

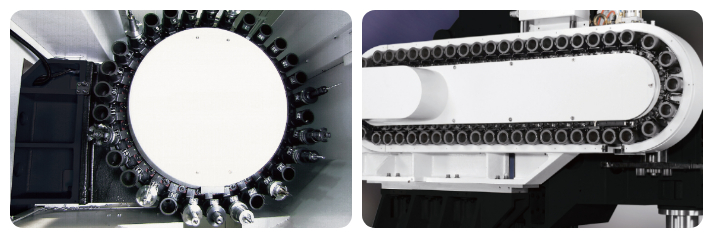

Reliable Automatic Tool Change

- Auto tool change(T-T): 1.8 sec.

- 24T Disk type as a standard

- 30T Disk type / 48T Chain type (opt.)

Efficient Chip Removal System

- Equipped with triple-chip augers as a standard.

- Dual-chip augers as an option.

Compare

×

Product has been added to compare

You can select up to 5 products or view the results directly.