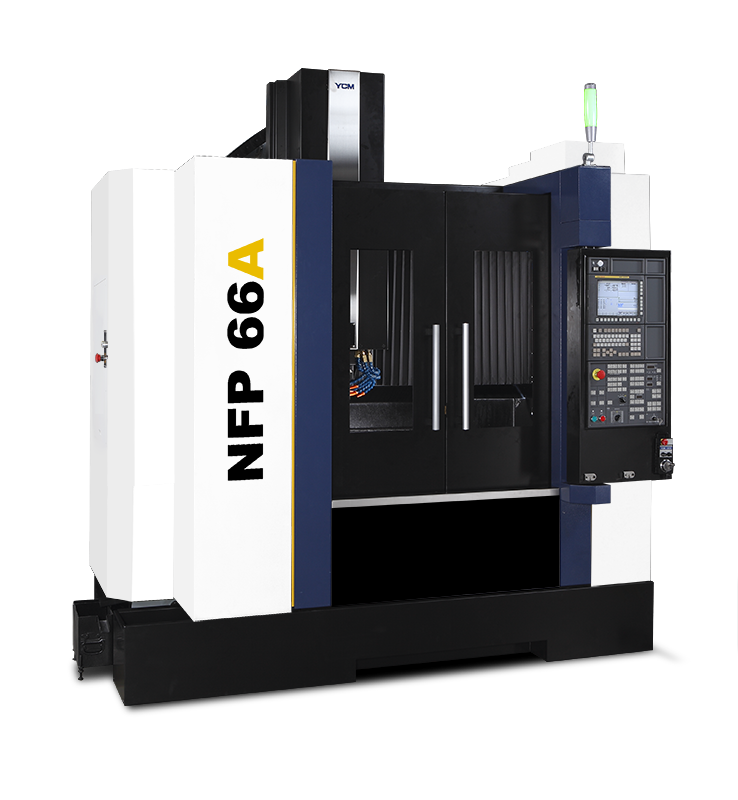

NFP66A

Product

ProductInfo

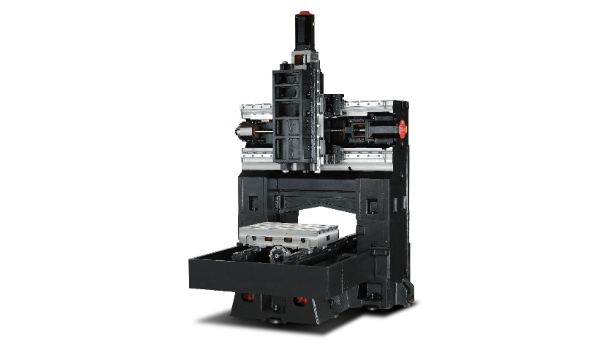

Reinforced Body Structure

- FEM analysis strengthens the structure of the machine to provide the best cutting rigidity.

- Box-shape and double column structure design reduce thermal deformation.

- Less Z-axis overhang ensure optimal machine stability.

High Precision Axial Movement

- The 4 million-pulse/rev high-resolution encoders in all axes enable the utmost precision status.

- The enlarged roller bearing linear motion guides perform extreme rigidity.

- High precision ballscrews ensure high speed high precision axial movements.

Built-in Motorized Spindle

- Low vibration and optimal head isolation reduces thermal deformation resulting in excellent finish while maximizing both spindle and tool life under hard milling conditions.

- Max. spindle speed up to 40,000 rpm (opt.).

- Double contact spindle taper ensures heavy-duty cutting performance and machining accuracy

- Highly reliable helical disc spring design for better spindle balance and life.

- Rear bearing floating design decreases thermal deformation at high speed.

- Design for dynamic balance of spindle provides ultimate cutting rigidity.

- Micro oil-air lubrication system minimizes thermal deformation and prolongs spindle life.

Spindle Thermal Compensation

- Built-in STC (spindle thermal compensation) function, control deviation under 5 μm.

Compare

×

Product has been added to compare

You can select up to 5 products or view the results directly.