NXV1270A

Product

ProductInfo

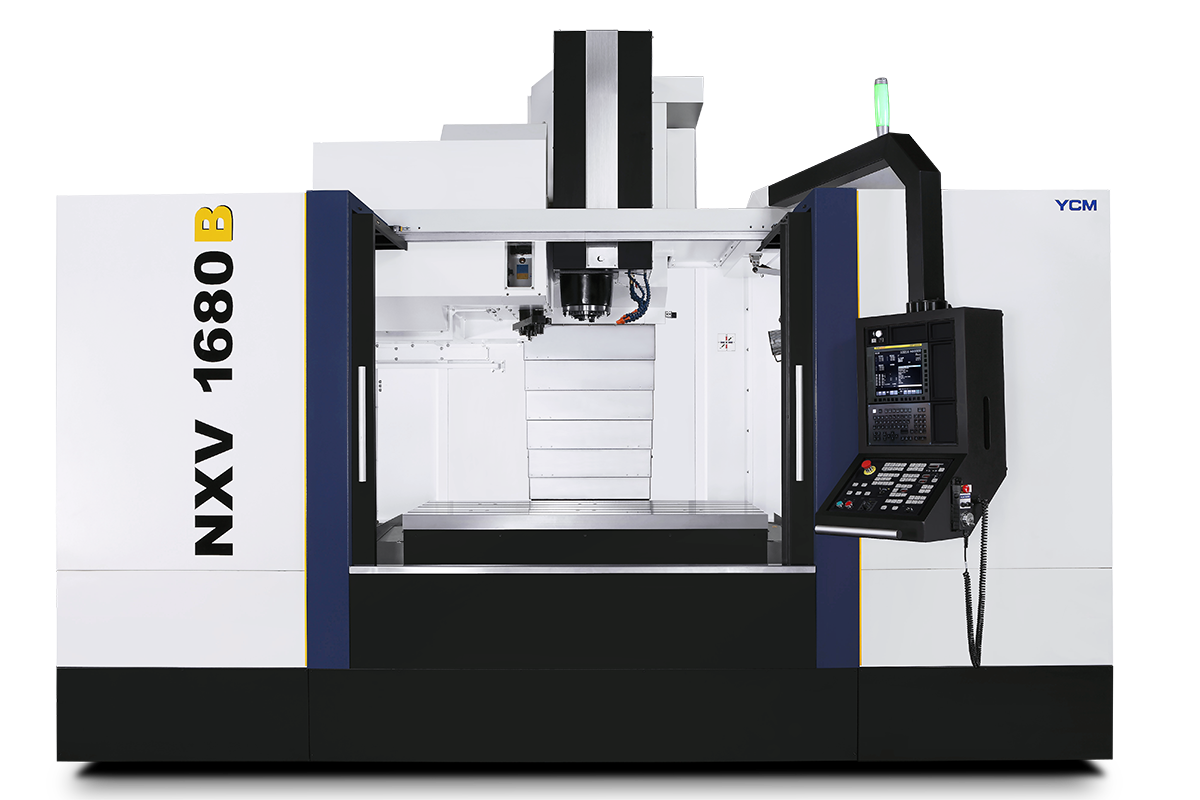

- FEM analysis is adopted to ensure the best mass arrangement and rib construction of the machine for constant stability under the intensive load of heavy-duty cutting.

- All axial AC servo motors equipped with Absolute Positioning Encoders, no zero return needed

- Direct drive provides backlash free, best accuracy, reliability and stability.

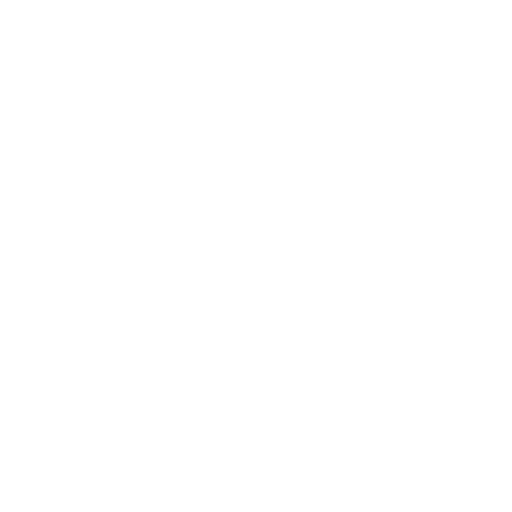

- Robust roller linear guideways applied on 3 axes.

- 6 blocks design on X-axis can easily support workpieces weighing up to 1,500 kg.

- 4-linear guideways on Y-axis with superior large span ensures the best dynamic balance.

- Rigid dual-wall castings on saddle

- Wide base structure with 10 leveling pads.

- The compact structure enables excellent floor space utilization

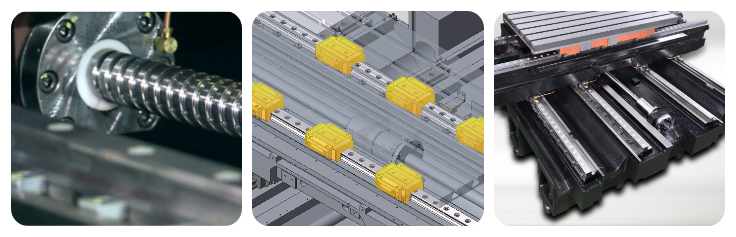

IDD Spindle Design: HIGH PRECISION HIGH SPEED

- The unique IDD spindle design offers smooth reliability at high speed.

- Ceramic bearings do not just boost the spindle speed, but also achieve high axial and radial rigidity, which fulfill strict machining requirements on heavy cutting, drilling and tapping.

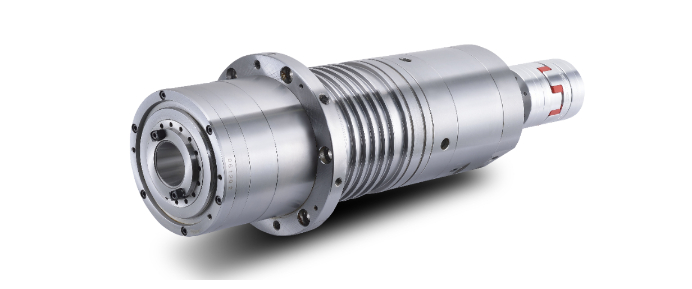

High Stability Tool Magazine

- Absolute encoder ATC system provides high stability and speed.

- Inverter controlled, prevents tool change speed from changing under different power supply frequency.

- Tool change speed can be adjustable for heavy tools.

- Auto Tool Change (T-T): 1.8 sec.

- Tool Magazine Capacity: 24T (30T/48T/60T opt.)

Automatic Tool Magazine Door Design

- Driven by pneumatic cylinder.

- Prevent coolant and chips from entering tool magazine.

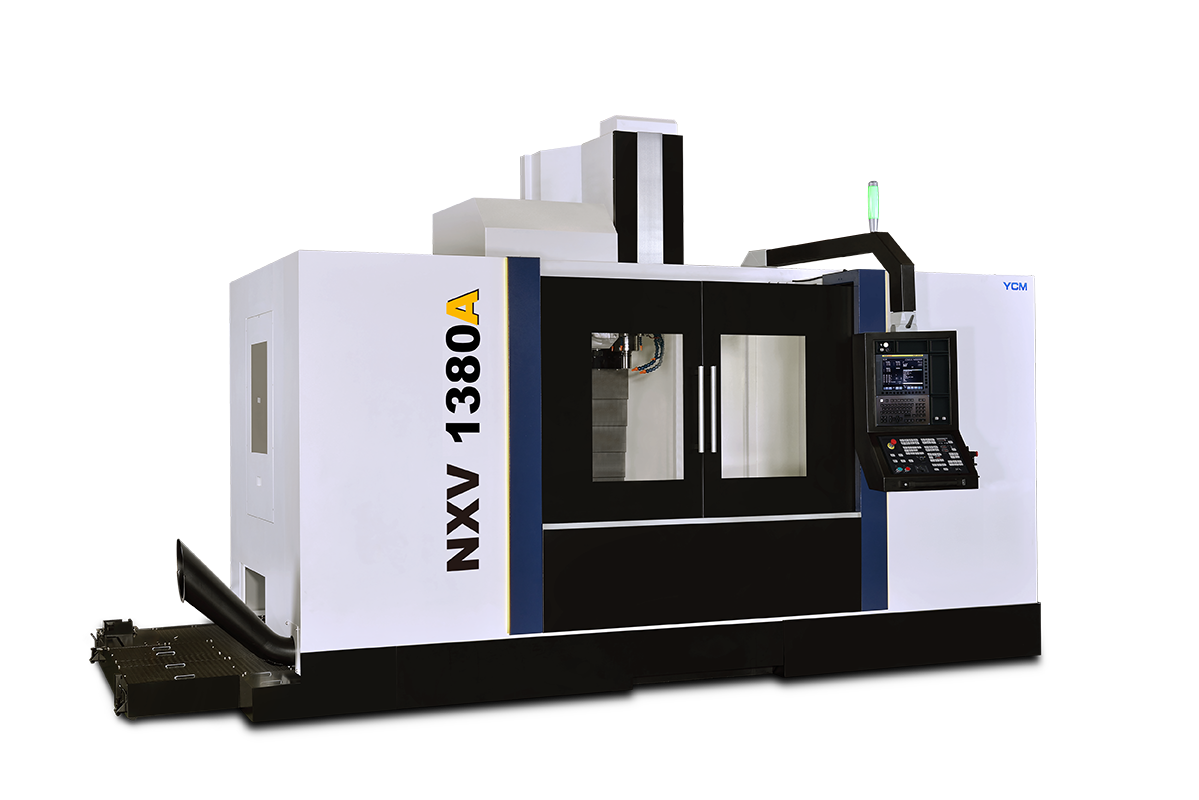

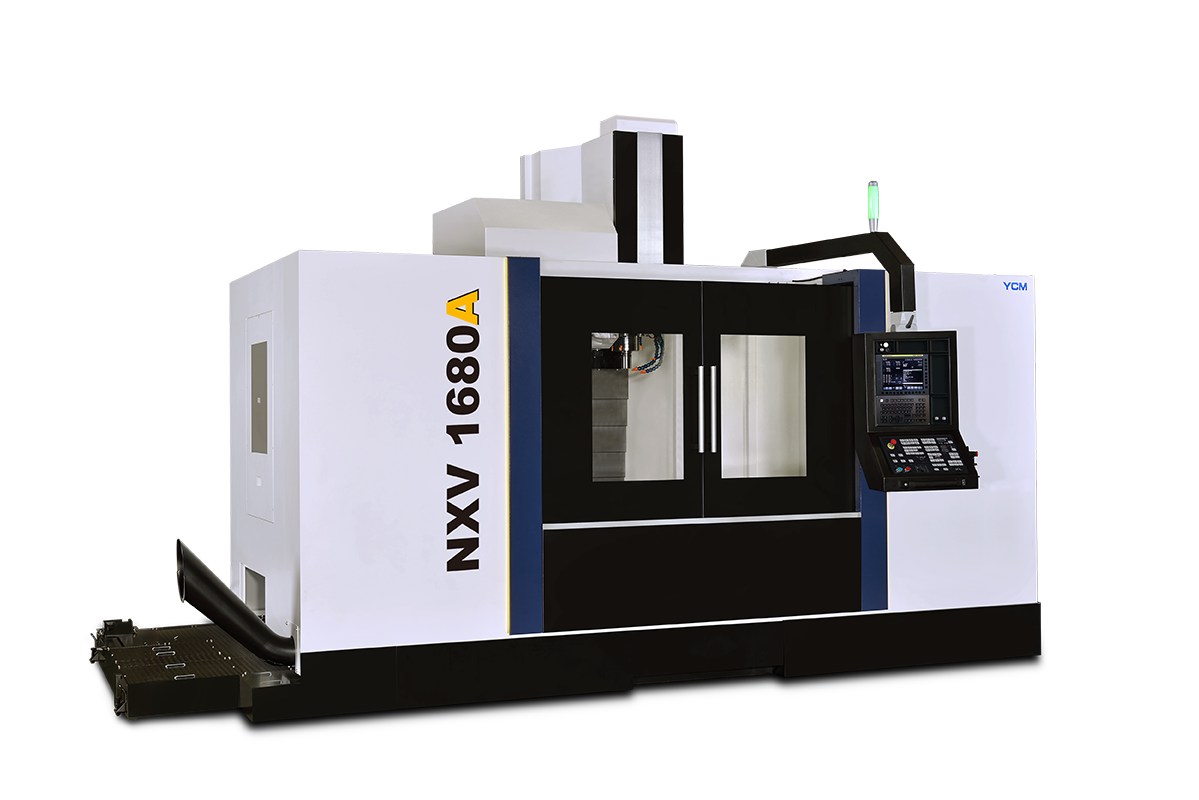

Brand New Exterior Design

- Full enclosure exterior (including top cover).

- Convertible side window for convenient chip removal.

- Aesthetic rear cover design.

- Coolant shower for efficient chip removal <NXV Series std.>

- Penta chip augers (4 Y-axial 1 X-axial) ensure fluent chip removal prevent chips from piling up. [Quad chip augers (4 Y-axial Chip Conveyor) opt.]

Compare

×

Product has been added to compare

You can select up to 5 products or view the results directly.