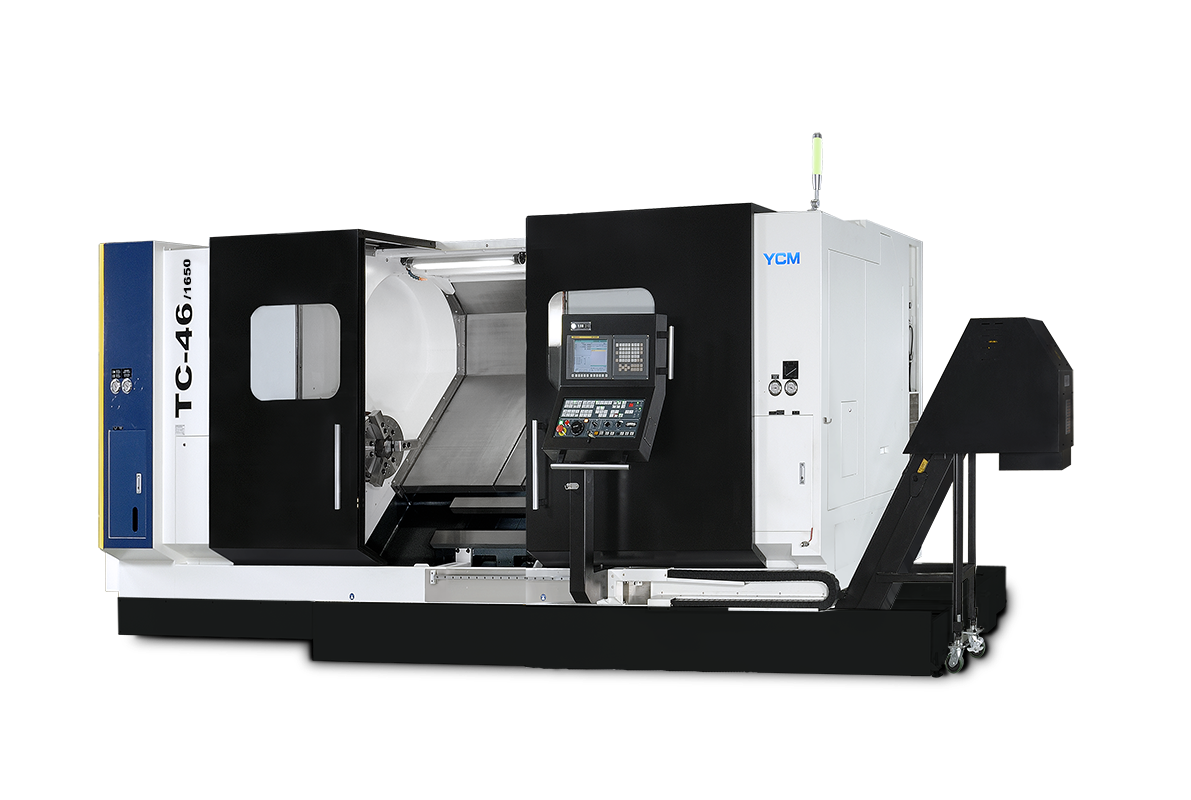

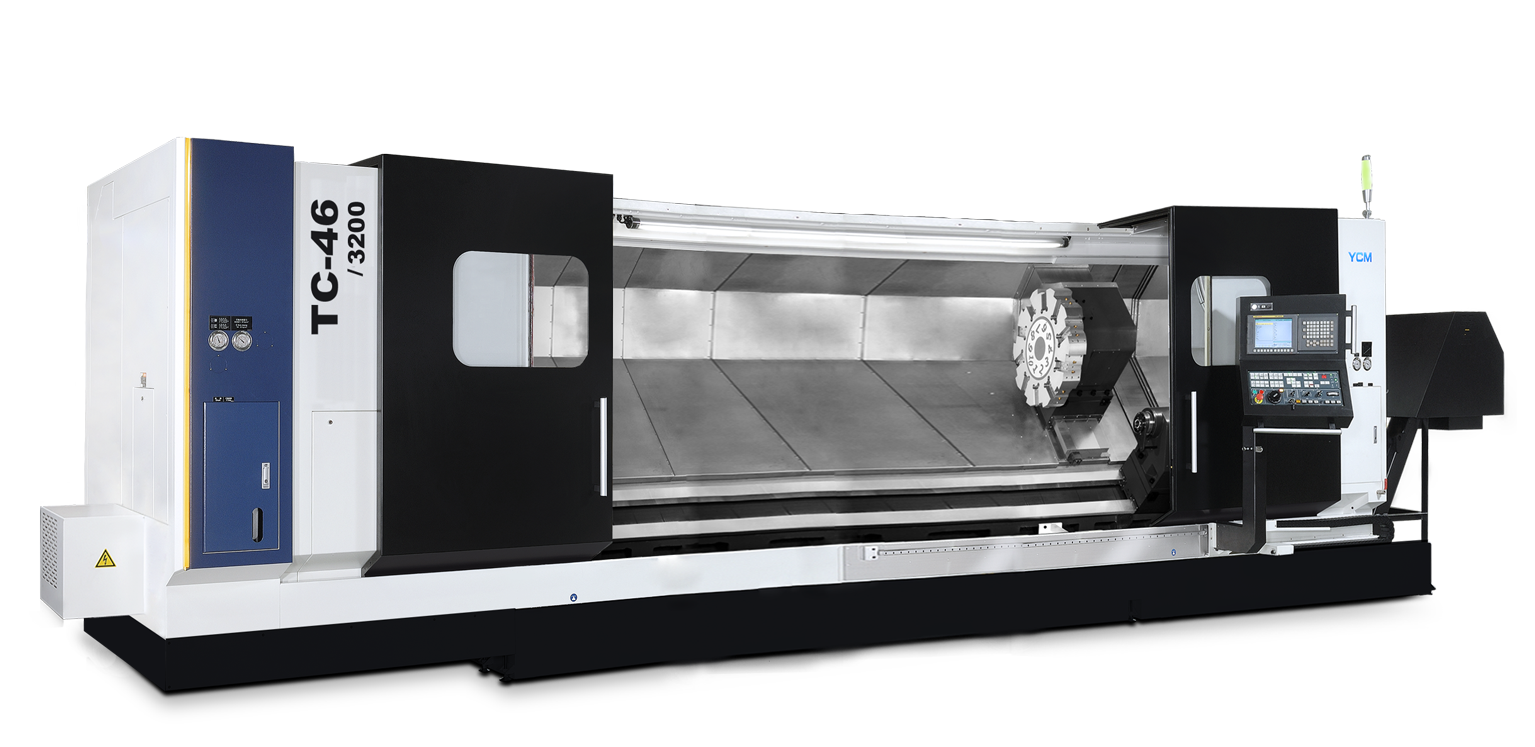

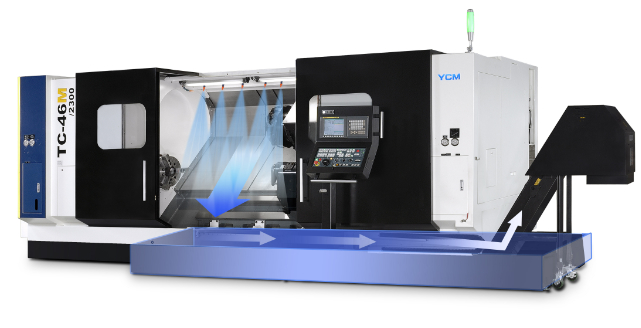

TC-46M/3200

Product

ProductInfo

- With years of experience, combining advanced technology and facilities, YCM has successfully developed highly rigid CNC Turning Centers, TC-46M. TC-46M is specially designed for producing large workpieces with high accuracy, suitable for valve and hydraulic components, shipbuilding, automobiles, construction and energy industries. What's more, TC-46M is equipped with C-axis and motorized turret that provides a wide range of complex milling functions.

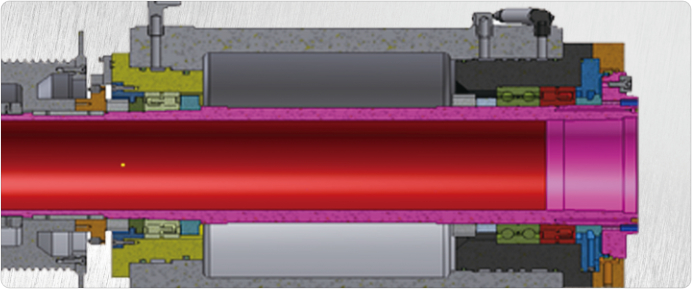

Perfect Spindle Design

- Equipped with A2-11 spindle nose and 15" chuck. (18"/21"/24" chick or customized fixture is optional.)

- The chuck is operated by pedal switch for more safety and user-friendly.

- The clamping pressure can be adjusted by workpiece shape and materal.

- Extra large bearing with excellent rigidity for heavy duty cutting capability.

The Extra Large Front Bearing

- The extra large front bearing internaldiameter is ø180 mm to ensure the heavy duty cutting capability.

- Max. hole through spindle diameter is ø130 mm.

- Max. hole through draw bar is ø117 mm.

Big Bore Hole Through Design (opt.)

- A2-15 spindle of Big bore hole for flexible chuck 15"/18"/21"/24", hole through Spindle ø182 mm ø7.17".

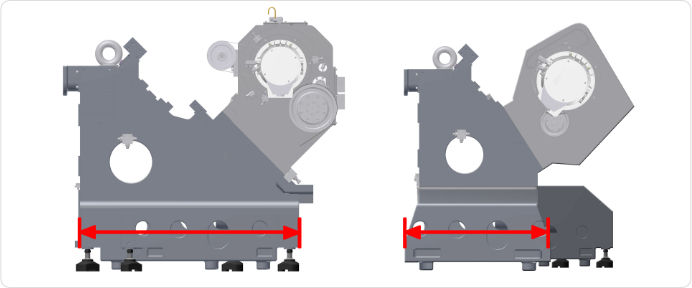

Rigid Structure Design

- MEEHANITE® casting frame through FEM analysis for one piece torque tube and 45 degree slant bed ensures the best rigidity and eliminates casting distortion.

- Z-axis design with an extra wide distance o f 620mm between guideways offers the highest rigidity.

- The box way base of 950mm is suitable for heavy duty machining and powerful chip removal.

Central Lubrication System

- The slide ways of X/Z-axis and ball screws are lubricated. Built-in alarm will be occurred when the lubrication oil is insufficient.

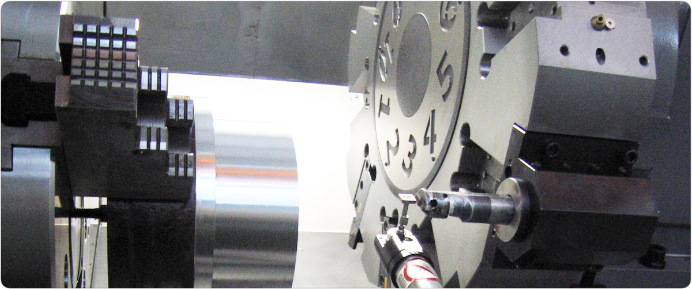

Automatic Tool Pre-setter Reduces Setup Time (Opt.)

- Optional automatic tool pre-setter reduces setup time by minimizing skim cuts and entering tool offsets.

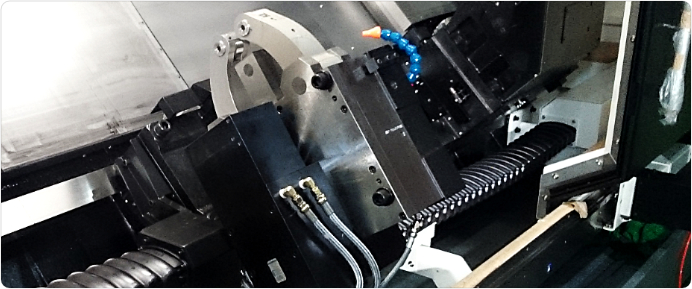

The Smoothest X-axis Movement and Prevents Turret Drop

- The hydraulic balance cylinder on X-axis ensures the smoothest axial movement and brake system prevents the turret from dropping when the power is suddenly off.

- With the double nuts design, the ball screws on the X/Z-axis provide the highest rigidity.

- The optional safety clutch will disassemble the ball screw from motor to protect the ball screw during a crash.

- YCM

Efficient Chip Disposal System

- With slanted design and superb chip removal space under the spindle, it is more easiler to clean chips.

- High pressure coolant is supplied for optimal chip removal.

- Shower coolant from the roof removes the chips from the chuck and telescopic guideway cover. (opt.)

Programmable tail stock

- MT-5 fixed quill with live center is standard, high rigidity rotary quill with dead center is optional.

- Tail stock using dual cylinder to clamp the guideways for prevent tail stock skid during machining. Using hydraulic connect bar to link the tail stock and carriage during tail stock positioning to save effort and time.

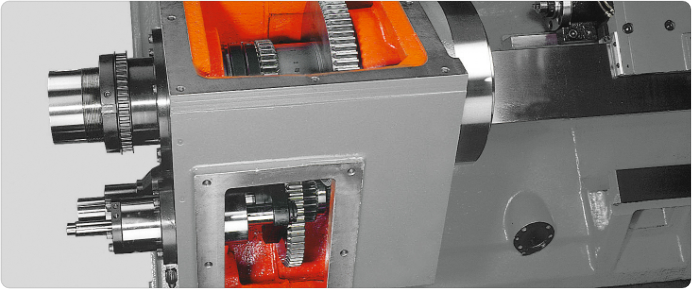

Fast & Reliable Motorized Turret

- 12 tools capacity with BMT 85 tooling system.

- Max. live tool power 15/18.5/22 kW 20/25/30 HP with Max. speed 3,000 rpm.

- Servo drive turret for high speed index.

- Hydraulic clamping turret with 3-piece large clutch for heavy duty cutting.

Powerful 2 speed Gear-head Spindle and Head Cooling

- Spindle quill /Gearbox with oil-cooling system for excellent thermal stability.

- Spindle motor power 30/37 kW 40/50 HP with 2 speed gear box.

- Max. torque380 kgf-m。

- C-axis with rotary encoder for high positioning 0.001 degree to provide excellent milling accuracy.

Compare

×

Product has been added to compare

You can select up to 5 products or view the results directly.

low.png)

low.png)