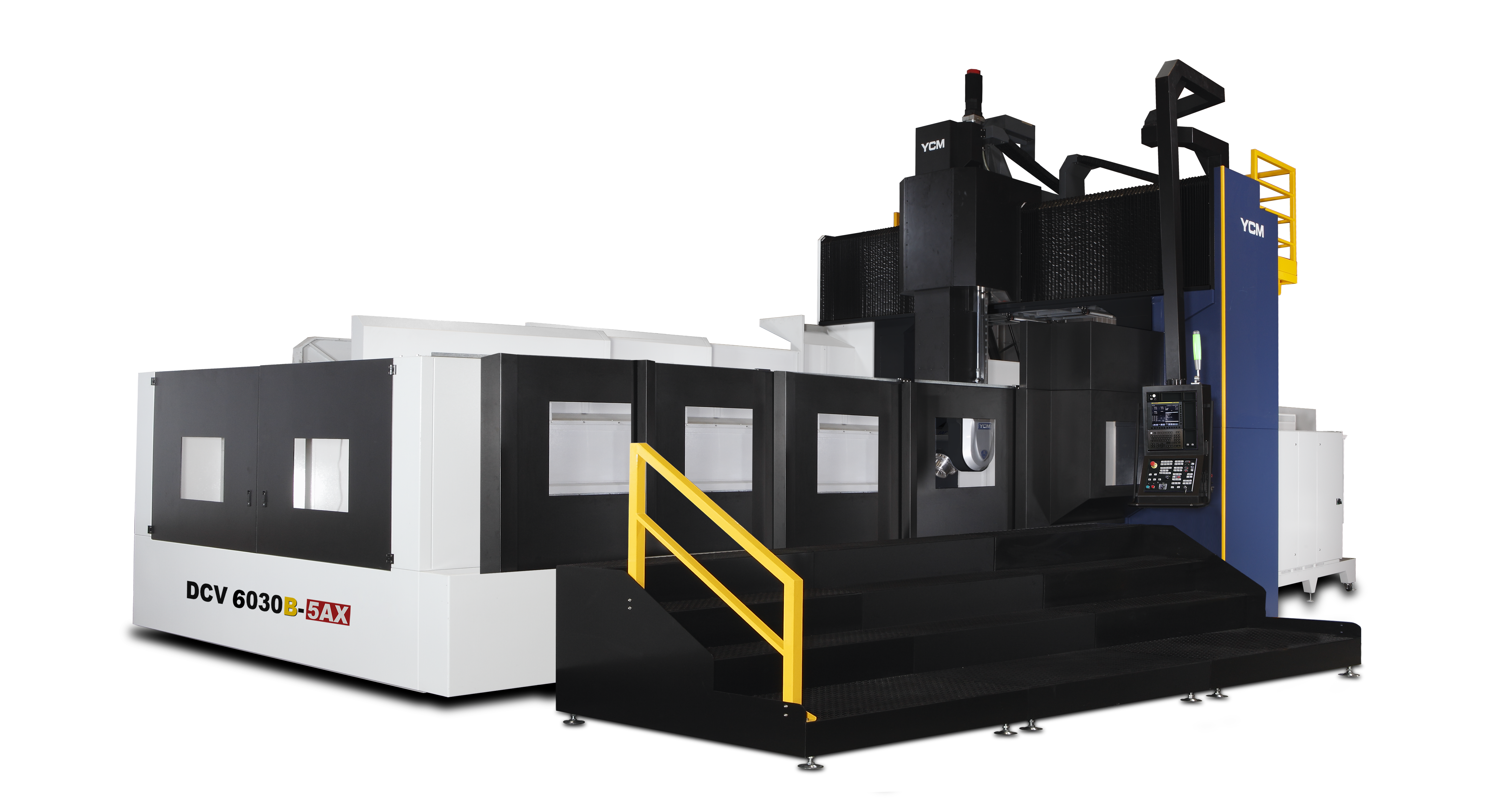

DCV4030B-5AX

Product

ProductInfo

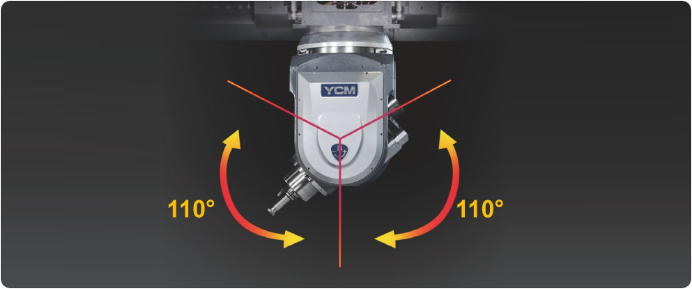

5AX ROBO I Achieves Perfect 3D Contouring Operations

- High rigidity symmetrical fork type structure design minimizes heat deformation during heavy cutting applications.

- The main structure is made of superior nodular graphite cast iron.

- High dynamic universal milling head, built-in motorized spindle with HSK-A100 taper offers max. spindle speed 10,000 rpm.

- Coolant through spindle system: 20 bar (opt.)

- Superb spindle coolant system.

High Rigidity B/C Axis

- Direct drive motor design delivers high torque, low backlash and perfect clamping capacity.

- HEIDENHAIN encoder enhances the cutting accuracy.

- Disc type hydraulic clamping device.

- Rotary joint design prevents the damage on the hydraulic tubes caused during rotation.

- Double direction roller bearings for perfect cutting rigidity.

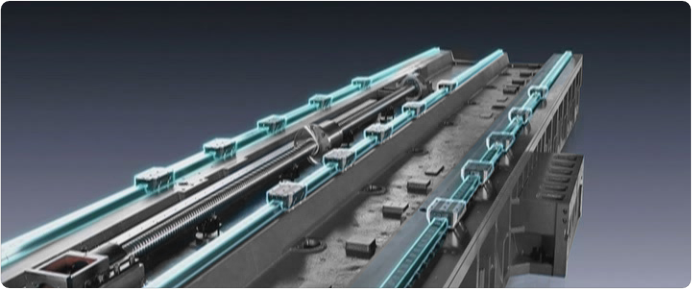

Superb Body Structure & X/Y/Z Guideways Design

- Massive MEEHANITE® casting through FEM analysis offers exceptional damping capacity.

- Direct drive gearbox design on X/Y/Z axis offers smooth axial response, high torque, and low backlash.

- Extra wide column base with boots design.

- Equipped with roller type guideways and numerous slider blocks for great load capacity and cutting rigidity.

HEIDENHAIN Control

- 5-axis simultaneous control by HEIDENHAIN TNC640 increases efficiency, tool life, and cutting accuracy.

- Program memory hard disk with 21 GB.

- Tool center point management [TCPM]

- Dynamic collision monitoring [DCM]

- DXF converter (opt.)

Unique Isolated Direct Drive Design

- 10,000rpm IDD spindle is optional to be equipped with DCV series. Driven by 46kW dual step AC digital spindle motor, the spindle is able to reach max. 36.04kgf-m torque output at 500rpm.

- Unique IDD design offers low spindle vibration and optimal heat isolation that results in excellent accuracy after longterm operation.

Compare

×

Product has been added to compare

You can select up to 5 products or view the results directly.

_(%E5%85%A8%E5%AF%86)%E6%94%B9%E7%BE%8E%E5%AD%B8%E8%89%B2.png)

_(%E5%85%A8%E5%AF%86)%E6%94%B9%E7%BE%8E%E5%AD%B8%E8%89%B2.png)

_%E9%BB%91.png)

_%E9%BB%91%E6%8B%B7%E8%B2%9D.png)

_%E9%BB%91.png)

_%E9%BB%91.png)

_%E9%BB%91.png)