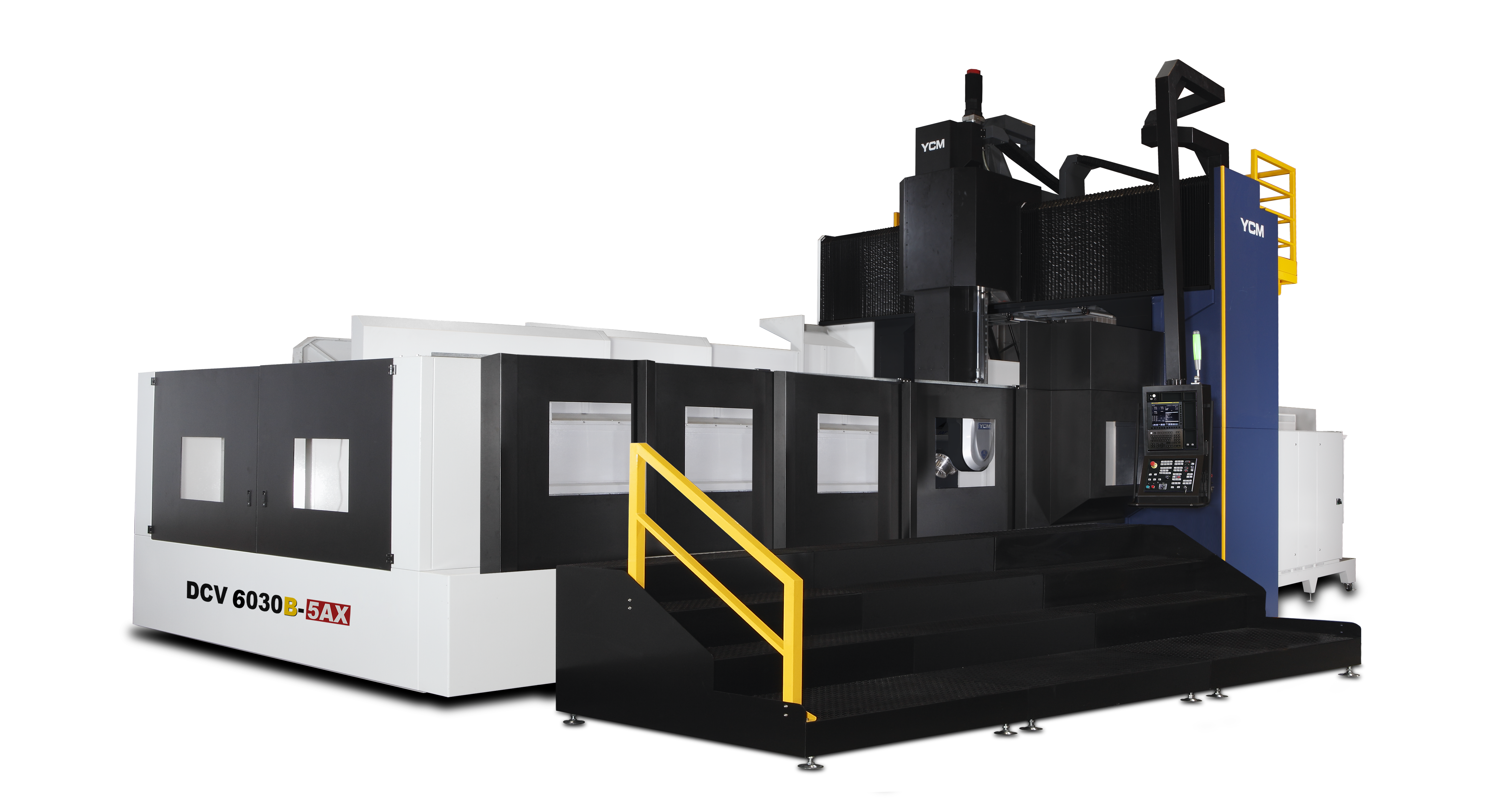

DCV5030B-5AX

Product

ProductInfo

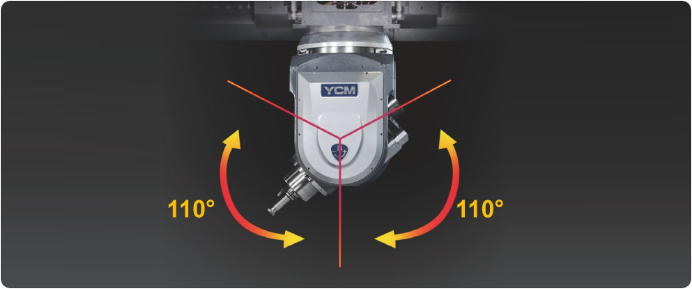

5AX ROBO I Achieves Perfect 3D Contouring Operations

- High rigidity symmetrical fork type structure design minimizes heat deformation during heavy cutting applications.

- The main structure is made of superior nodular graphite cast iron.

- High dynamic universal milling head, built-in motorized spindle with HSK-A100 taper offers max. spindle speed 10,000 rpm.

- Coolant through spindle system: 20 bar (opt.)

- Superb spindle coolant system.

High Rigidity B/C Axis

- Direct drive motor design delivers high torque, low backlash and perfect clamping capacity.

- HEIDENHAIN encoder enhances the cutting accuracy.

- Disc type hydraulic clamping device.

- Rotary joint design prevents the damage on the hydraulic tubes caused during rotation.

- Double direction roller bearings for perfect cutting rigidity.

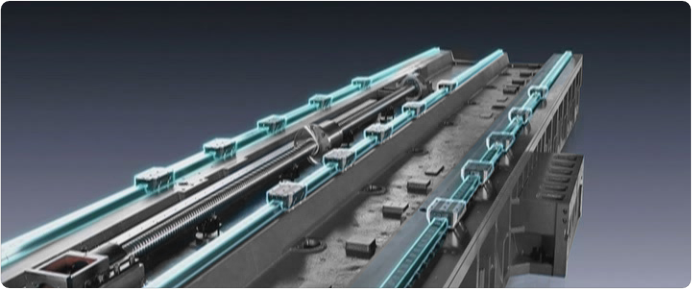

Superb Body Structure & X/Y/Z Guideways Design

- Massive MEEHANITE® casting through FEM analysis offers exceptional damping capacity.

- Direct drive gearbox design on X/Y/Z axis offers smooth axial response, high torque, and low backlash.

- Extra wide column base with boots design.

- Equipped with roller type guideways and numerous slider blocks for great load capacity and cutting rigidity.

HEIDENHAIN Control

- 5-axis simultaneous control by HEIDENHAIN TNC640 increases efficiency, tool life, and cutting accuracy.

- Program memory hard disk with 21 GB.

- Tool center point management [TCPM]

- Dynamic collision monitoring [DCM]

- DXF converter (opt.)

Unique Isolated Direct Drive Design

- 10,000 rpm IDD spindle is optional to be equipped with DCV series. Driven by 46 kW dual step AC digital spindle motor, the spindle is able to reach max. 36.04 kgf-m torque output at 500 rpm.

- Unique IDD design offers low spindle vibration and optimal heat isolation that results in excellent accuracy after longterm operation.

Compare

×

Product has been added to compare

You can select up to 5 products or view the results directly.

_(%E5%85%A8%E5%AF%86)%E6%94%B9%E7%BE%8E%E5%AD%B8%E8%89%B2.png)

_(%E5%85%A8%E5%AF%86)%E6%94%B9%E7%BE%8E%E5%AD%B8%E8%89%B2.png)

_%E9%BB%91.png)

_%E9%BB%91%E6%8B%B7%E8%B2%9D.png)

_%E9%BB%91.png)

_%E9%BB%91.png)

_%E9%BB%91.png)